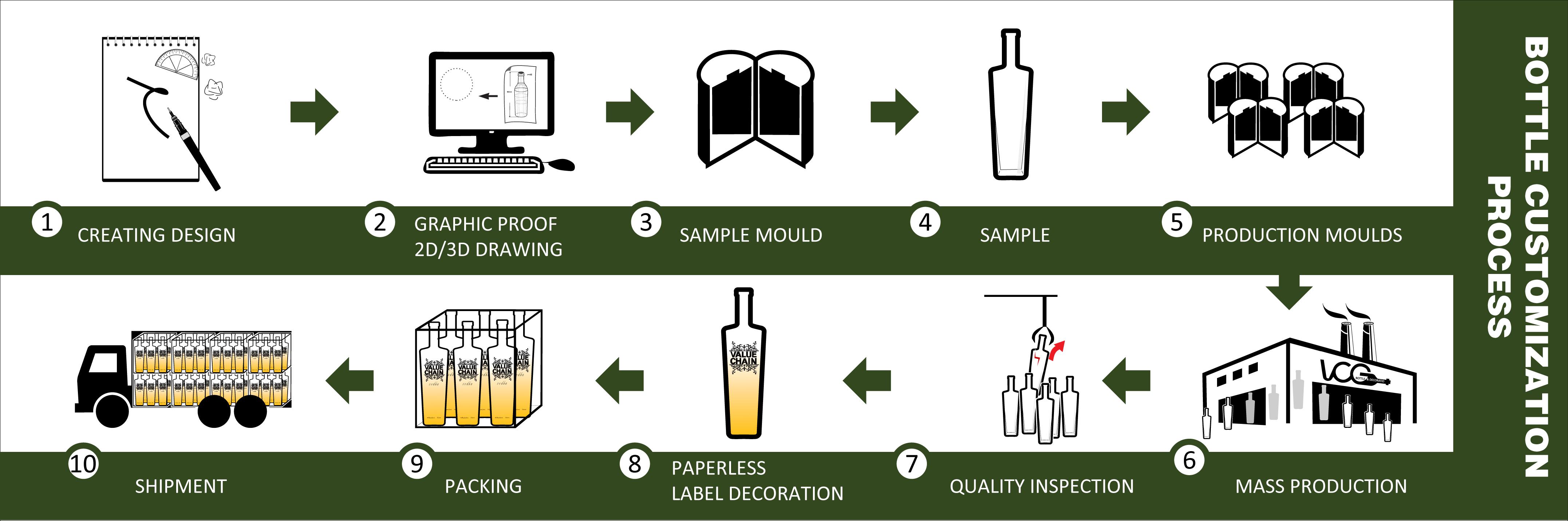

You can see the process of spirit bottle customization:

Step 1: Create technical drawing of the requested bottle shape (3-5 days) Or clients provide the drawing, VCG analyze the technical feasibility and adjust if necessary. (3 days)(Provide the label artwork for technical analysis if needed)

Step 2: Make 2D drawing for clients’ approval (1 day)

Step 3: Open sample mould / 1 set (15-20 days)

Step 4: Produce clear bottle samples for clients’ approval (5-7 days)

(Make decorated samples if needed /15 days )

Step 5: Order confirmed, finish mass production moulds / 10 sets (20 days)

Step 6: Clear bottle production (production time depends on the quantity)

Step 7: Quality checking and assurance

Step 8: Do paperless label printing if needed (QC & QA again)

Step 9: Packing for shipment

Step 10: Shipment

Our Advantage of custom bottle:

We have our own mould making plant, in this case, we can control the mould quality, cost and time directly, which means that clients can enjoy better mould quality, less mould cost and shorter mould making time.

Most of mould factories are using IRON to produce moulds for glassware industry, but the best material for mould is STEEL, which is what we start to use in 2013. We'd rather surrender part of the profits to get the best quality of moulds as this is the foundation of stable product quality.